รายละเอียดสินค้า:

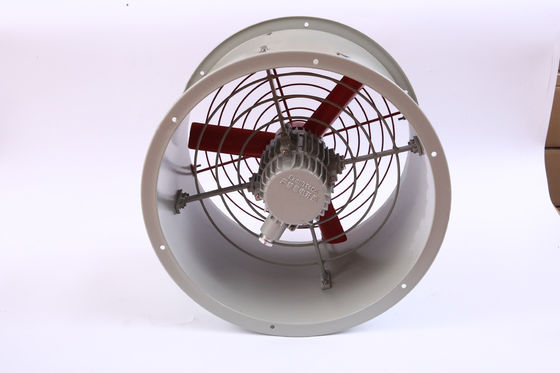

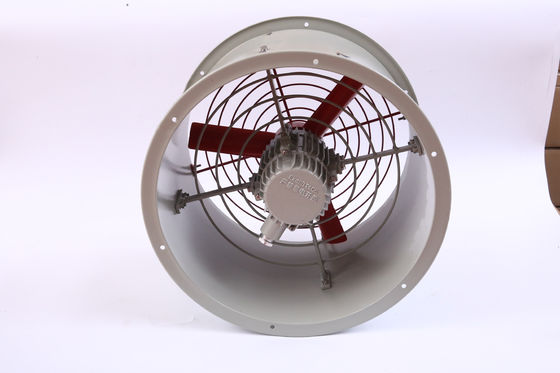

ขอแนะนำผลิตภัณฑ์ชั้นนำของเราในกลุ่มพัดลมระบายอากาศกันระเบิด - โซลูชันที่ดีที่สุดสำหรับสภาพแวดล้อมอุตสาหกรรมที่ต้องการการระบายอากาศที่ปลอดภัยและมีประสิทธิภาพ พัดลมประสิทธิภาพสูงนี้ได้รับการออกแบบมาเพื่อตอบสนองความต้องการที่เข้มงวดที่สุด พร้อมทั้งรับประกันการทำงานที่ปลอดภัยและเชื่อถือได้

พัดลมระบายอากาศกันระเบิดติดตั้งมอเตอร์พัดลมระบายอากาศทรงพลังที่ให้ประสิทธิภาพและความทนทานเป็นพิเศษ มอเตอร์ได้รับการออกแบบมาโดยเฉพาะเพื่อให้ทนทานต่อสภาวะที่รุนแรงของสภาพแวดล้อมทางอุตสาหกรรม ให้การทำงานที่เชื่อถือได้เป็นระยะเวลานานโดยไม่กระทบต่อประสิทธิภาพ

คุณสมบัติที่สำคัญประการหนึ่งของผลิตภัณฑ์นี้คือเครื่องทำความร้อนไฟฟ้ากันระเบิดในตัว ซึ่งช่วยเพิ่มฟังก์ชันการทำงานของพัดลมโดยให้ความสามารถในการทำความร้อนเพิ่มเติม สิ่งนี้ทำให้มั่นใจได้ว่าพัดลมสามารถรักษาอุณหภูมิที่เหมาะสมในสภาพแวดล้อมที่เป็นอันตรายได้อย่างมีประสิทธิภาพ ทำให้เหมาะสำหรับการใช้งานทางอุตสาหกรรมที่หลากหลาย

นอกจากนี้ แอคชูเอเตอร์ไฟฟ้ากันระเบิดที่รวมอยู่ในพัดลมระบายอากาศนี้ยังช่วยให้มั่นใจได้ถึงการควบคุมและการทำงานที่แม่นยำ ทำให้ผู้ใช้สามารถปรับการตั้งค่าพัดลมได้อย่างง่ายดาย คุณสมบัตินี้ช่วยเพิ่มความสามารถในการใช้งานโดยรวมของพัดลมและมีส่วนช่วยในประสิทธิภาพในการรักษาสภาพแวดล้อมการทำงานที่ปลอดภัยและสะดวกสบาย

คุณสมบัติ:

- ชื่อผลิตภัณฑ์: พัดลมระบายอากาศกันระเบิด

- เส้นผ่านศูนย์กลาง: 200-750 มม.

- เงื่อนไขการชำระเงิน: 50% + 50%

- แรงดันไฟฟ้า: 220v/380v

- รุ่น: BAF

- การป้องกัน: IP54 WF1/WF2

พารามิเตอร์ทางเทคนิค:

| ประเภท |

BAF |

| แรงดันไฟฟ้าที่กำหนด |

220/380VAC |

| การป้องกัน |

IP54 WF1/WF2 |

| อัตรา Ex |

Ex d IIB T4 Gb |

| เส้นผ่านศูนย์กลาง |

200-750 มม. |

| รุ่น |

BAF |

| การติดตั้ง |

ผนัง, ท่อ, เสา, คงที่ |

| RPM |

1450r/m |

| เงื่อนไขการชำระเงิน |

50% + 50% |

| เครื่องหมาย Ex |

Ex db IIC T4 Gb |

การใช้งาน:

1. อุตสาหกรรมปิโตรเลียม เคมี และก๊าซธรรมชาติ

นี่คือพื้นที่หลักของไฟส่องสว่างกันระเบิดและการใช้งานที่แพร่หลายที่สุด

การสกัดและการกลั่นปิโตรเลียม: แท่นขุดเจาะ โรงงานผลิตน้ำมัน โรงกลั่นน้ำมัน สถานีบริการน้ำมัน สถานีสูบน้ำมัน ฯลฯ สถานที่เหล่านี้เต็มไปด้วยสารที่ติดไฟได้และระเบิดได้ เช่น น้ำมันดิบ ก๊าซธรรมชาติ น้ำมันเบนซิน ดีเซล และไฮโดรเจนซัลไฟด์

การผลิตสารเคมี: โรงงานเคมี โรงงานผลิตยาฆ่าแมลง โรงงานปุ๋ย โรงงานเภสัชกรรม โรงงานสี และโรงงานเรซิน มีการสร้างก๊าซเคมีและฝุ่นละอองที่ติดไฟได้และระเบิดได้จำนวนมากในระหว่างการผลิต การแปรรูป การจัดเก็บ และการขนส่ง

ก๊าซธรรมชาติ: โรงงานแปรรูปก๊าซธรรมชาติ สถานีเติมก๊าซธรรมชาติอัด (CNG)/ก๊าซธรรมชาติเหลว (LNG) และห้องวาล์วท่อก๊าซธรรมชาติ

2. การขุด: เหมืองถ่านหิน: อุโมงค์ใต้ดิน หน้าเหมือง ช่องระบายอากาศ และสถานีขนส่ง เหมืองถ่านหินมีมีเทน (ก๊าซ) และฝุ่นถ่านหิน ซึ่งเป็นแหล่งที่ระเบิดได้สูง

เหมืองอื่นๆ: แร่โลหะ (เช่น ผงอะลูมิเนียมและแมกนีเซียม) และเหมืองกำมะถันก็มีสภาพแวดล้อมที่มีฝุ่นละอองที่ติดไฟได้เช่นกัน

3. อุตสาหกรรมทหารและอวกาศ

สถานที่ผลิต จัดเก็บ และทดสอบสำหรับดินปืน วัตถุระเบิด และกระสุน

อุตสาหกรรมอวกาศ: สถานีบริการน้ำมัน โรงเก็บเครื่องบิน (ซึ่งอาจมีการสะสมไอระเหยของเชื้อเพลิงในระหว่างการบำรุงรักษา) โรงงานผลิตเชื้อเพลิงจรวด ฯลฯ

4. การแปรรูปธัญพืชและอาหาร

นี่คืออุตสาหกรรมที่มักถูกมองข้ามแต่มีความเสี่ยงสูงมาก

อุตสาหกรรมแปรรูปธัญพืช: โรงโม่แป้ง โรงงานน้ำตาล โรงงานแป้ง โรงงานแปรรูปอาหาร โรงเก็บธัญพืช ฯลฯ เมื่อฝุ่นธัญพืชในอากาศ (เช่น แป้ง น้ำตาลผง และแป้ง) ถึงความเข้มข้นบางอย่าง อาจทำให้เกิดการระเบิดของฝุ่นอย่างรุนแรงเมื่อสัมผัสกับแหล่งกำเนิดประกายไฟ

อุตสาหกรรมแปรรูปอาหาร: โรงงานผลิตน้ำมันพืช โรงเบียร์แอลกอฮอล์ ฯลฯ

5. อุตสาหกรรมสิ่งทอและการแปรรูปไม้

โรงงานสิ่งทอ: การแปรรูปเส้นใย เช่น ฝ้าย ลินิน และขนสัตว์ ทำให้เกิดเส้นใยและฝุ่นละอองที่ติดไฟได้จำนวนมาก

อุตสาหกรรมแปรรูปไม้: โรงเลื่อย โรงงานเฟอร์นิเจอร์ และโรงงานกระดาษสร้างฝุ่นไม้ที่ติดไฟได้

6. สภาพแวดล้อมที่เป็นอันตรายอื่นๆ

โรงบำบัดน้ำเสีย: ถังบำบัดน้ำเสีย สถานีสูบน้ำ และพื้นที่อื่นๆ อาจสร้างก๊าซที่ติดไฟได้และเป็นพิษ เช่น มีเทน (ก๊าซชีวภาพ) และไฮโดรเจนซัลไฟด์

ร้านทำสีรถยนต์: ห้องพ่นสีเต็มไปด้วยสีและไอระเหยของตัวทำละลายที่ติดไฟได้

คลังสินค้าและโลจิสติกส์: คลังสินค้า ท่าเรือ และอาคารผู้โดยสารที่ใช้ในการจัดเก็บวัสดุที่ติดไฟได้ เช่น สี แอลกอฮอล์ และตัวทำละลาย

ห้องปฏิบัติการ: ห้องปฏิบัติการเคมีและชีวภาพที่จัดการสารเคมีที่ติดไฟได้และระเบิดได้

การสนับสนุนและบริการ:

การสนับสนุนด้านเทคนิคและบริการผลิตภัณฑ์ของเราสำหรับพัดลมระบายอากาศกันระเบิดประกอบด้วย:

- ความช่วยเหลือจากผู้เชี่ยวชาญในการติดตั้งและตั้งค่า

- คำแนะนำในการแก้ไขปัญหาสำหรับปัญหาการดำเนินงานใดๆ

- การสนับสนุนการรับประกันและข้อมูล

- เคล็ดลับการบำรุงรักษาเพื่อให้มั่นใจถึงประสิทธิภาพสูงสุด

การบรรจุและการขนส่ง:

บรรจุภัณฑ์ผลิตภัณฑ์:

- พัดลมระบายอากาศกันระเบิดบรรจุในกล่องกระดาษแข็งที่แข็งแรงเพื่อความปลอดภัยในการขนส่ง

- แต่ละหน่วยถูกห่อด้วยวัสดุบรรจุภัณฑ์ป้องกันเพื่อป้องกันความเสียหายระหว่างการขนส่ง

ข้อมูลการขนส่ง:

- โดยทั่วไปคำสั่งซื้อจะดำเนินการภายใน 1-2 วันทำการ

- เรามีตัวเลือกการจัดส่งแบบมาตรฐานและแบบเร่งด่วนเพื่อตอบสนองความต้องการของคุณ

- เมื่อคำสั่งซื้อของคุณถูกจัดส่ง คุณจะได้รับหมายเลขติดตามเพื่อตรวจสอบสถานะการจัดส่ง

คำถามที่พบบ่อย:

ถาม: ชื่อแบรนด์ของพัดลมระบายอากาศกันระเบิดคืออะไร

ตอบ: ชื่อแบรนด์คือ Crown Extra

ถาม: หมายเลขรุ่นของพัดลมระบายอากาศกันระเบิดคืออะไร

ตอบ: หมายเลขรุ่นคือ BAF

ถาม: พัดลมระบายอากาศกันระเบิดผลิตที่ไหน

ตอบ: พัดลมผลิตในฉางโจว มณฑลเจียงซู ประเทศจีน

ถาม: พัดลมระบายอากาศกันระเบิดมีการรับรองอะไรบ้าง

ตอบ: พัดลมได้รับการรับรอง CE, RoHS และ ATEX

ถาม: เงื่อนไขการชำระเงินที่ยอมรับสำหรับการซื้อพัดลมระบายอากาศกันระเบิดคืออะไร

ตอบ: เงื่อนไขการชำระเงินที่ยอมรับ ได้แก่ T/T, D/A, D/P, Western Union และ MoneyGram

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!